S2000 Introduction

s2000 ·My S2000’s Journey:

I have owned my s2000 for coming up on 5 years now. It has been one hell of an ownership Journey from it starting as my daily driver in college, to being wrecked, and turning it into a track toy. Where I am going to pick up the story with my car is Senior year of college it is still my daily driver,but I have added some nice mods. It has new wheels and tires, new suspension, new brakes and brake lines, and modified exhaust. I drove it up Memphis for a track night with the SCCA. The event was well run, and I was put in the beginner class because I had never been in a track day before. I ran 3 of the 4 sessions of the day. On the last session I was on the main straight and the rubber seals on my oil filter blew out when I was going 100 mph. Oil hit my two right tires, and I spun for 300 feet hitting the wall 5 times all on the rear of the car.

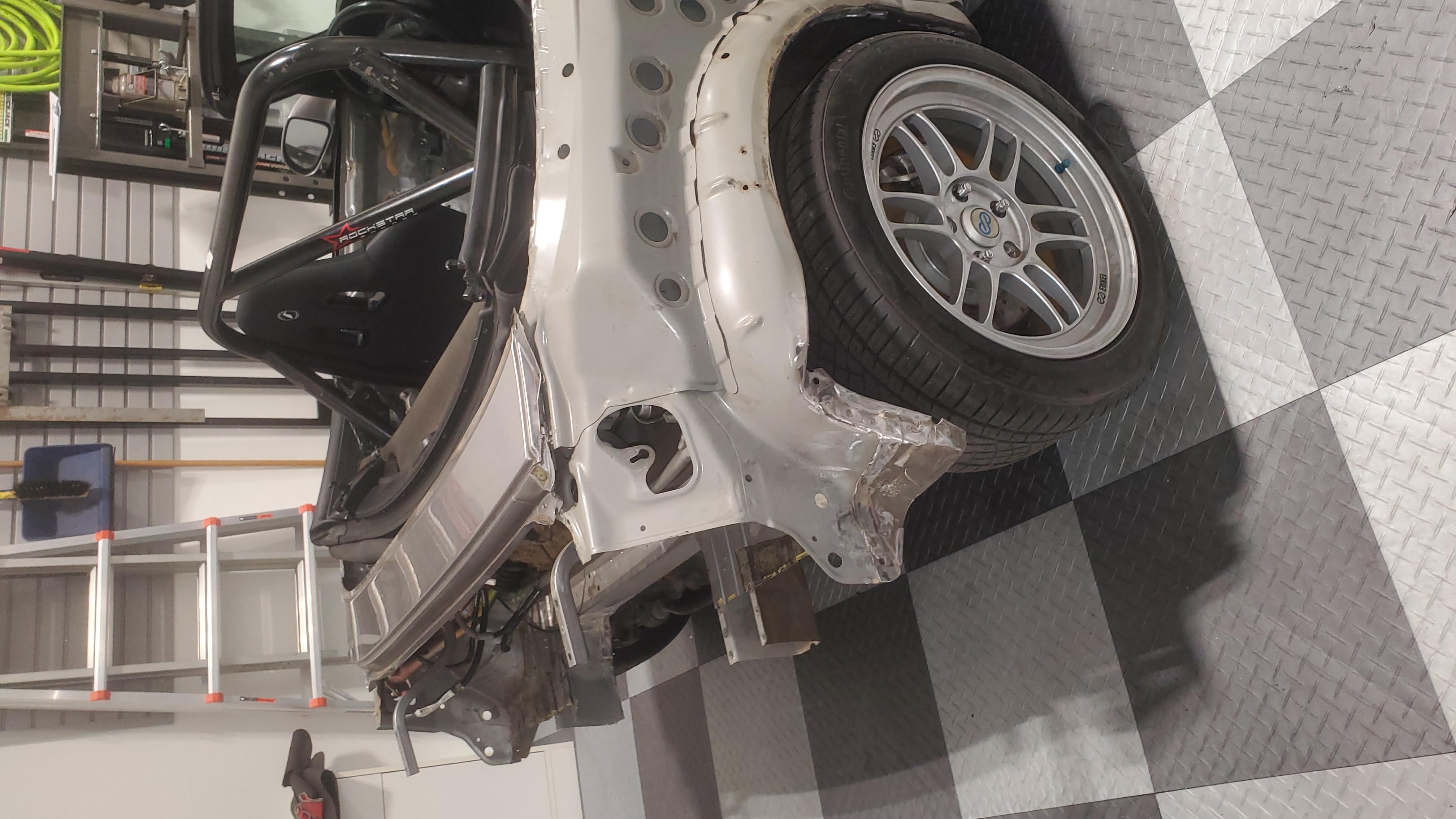

In the following months I shipped the wrecked car to my dad’s shop in Florida. I called around to local body shops to see if anyone would be interested in fixing it. No one wanted to touch it with a 10-foot pole. I found a rear clip for the car on ebay. It was everything from the back of the doors to the rear bumper. It was basically a chopped in half car that they shipped on a pallet that showed up to the shop.

From there we started cutting away all the rust and crumpled car. It left us with a go cart car. The rear frame rails had about a foot cut off of them.

Next was to prep the donor car everything that was not the trunk, rear quarter panels, rear frame rails, or supporting inner structure was cut away. This also included on both cars the donor and the crashed one, drilling out all 200 plus spot welds that held the body panels on. I bought the shop manual for this car and it was a real life-saver because it showed in the body manual where the spot welds were. Even when they were not visible.

Once the donor clip was ready to go it was trail and error process trying to get the new piece to fit on the rest of the car.

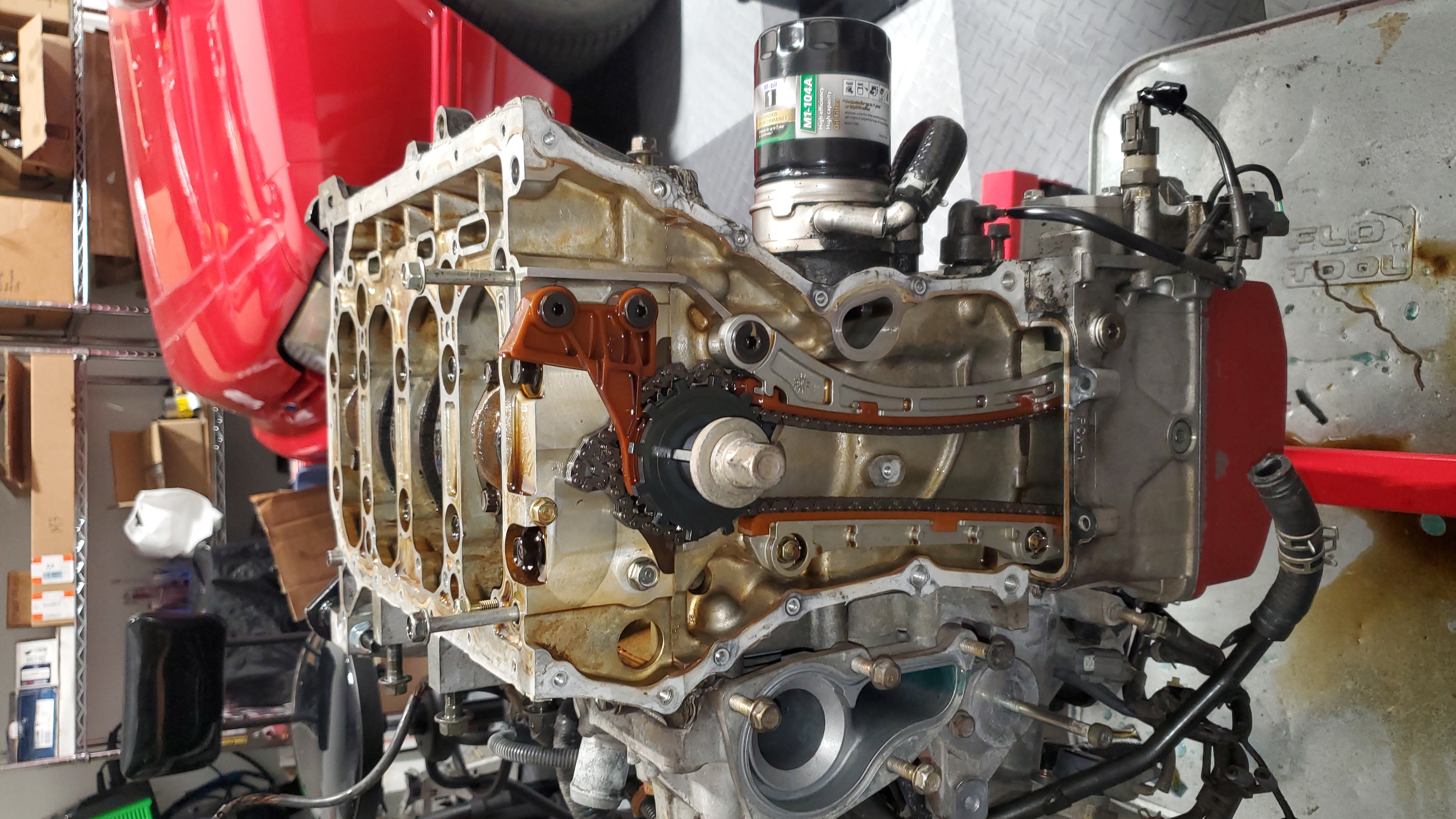

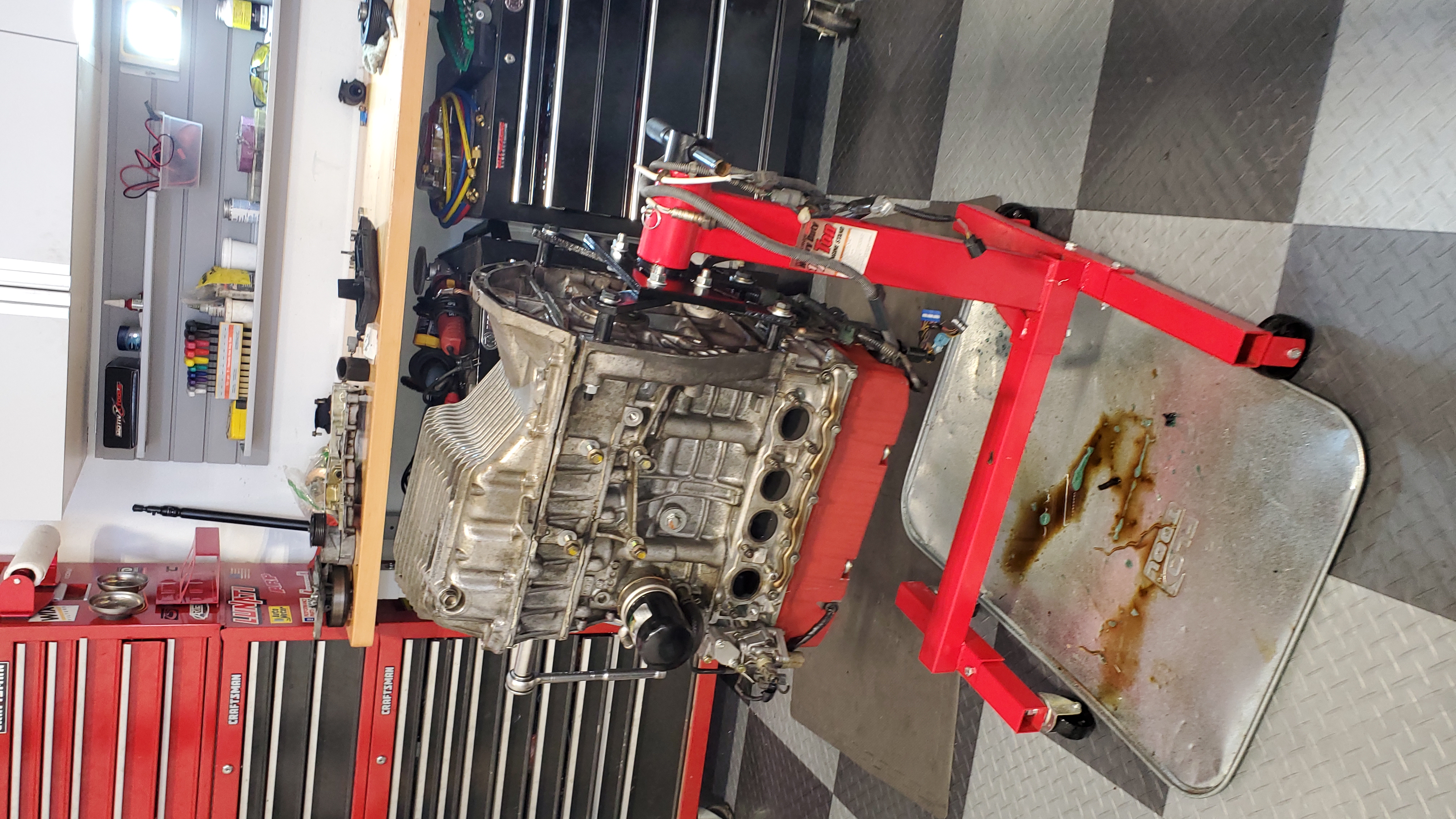

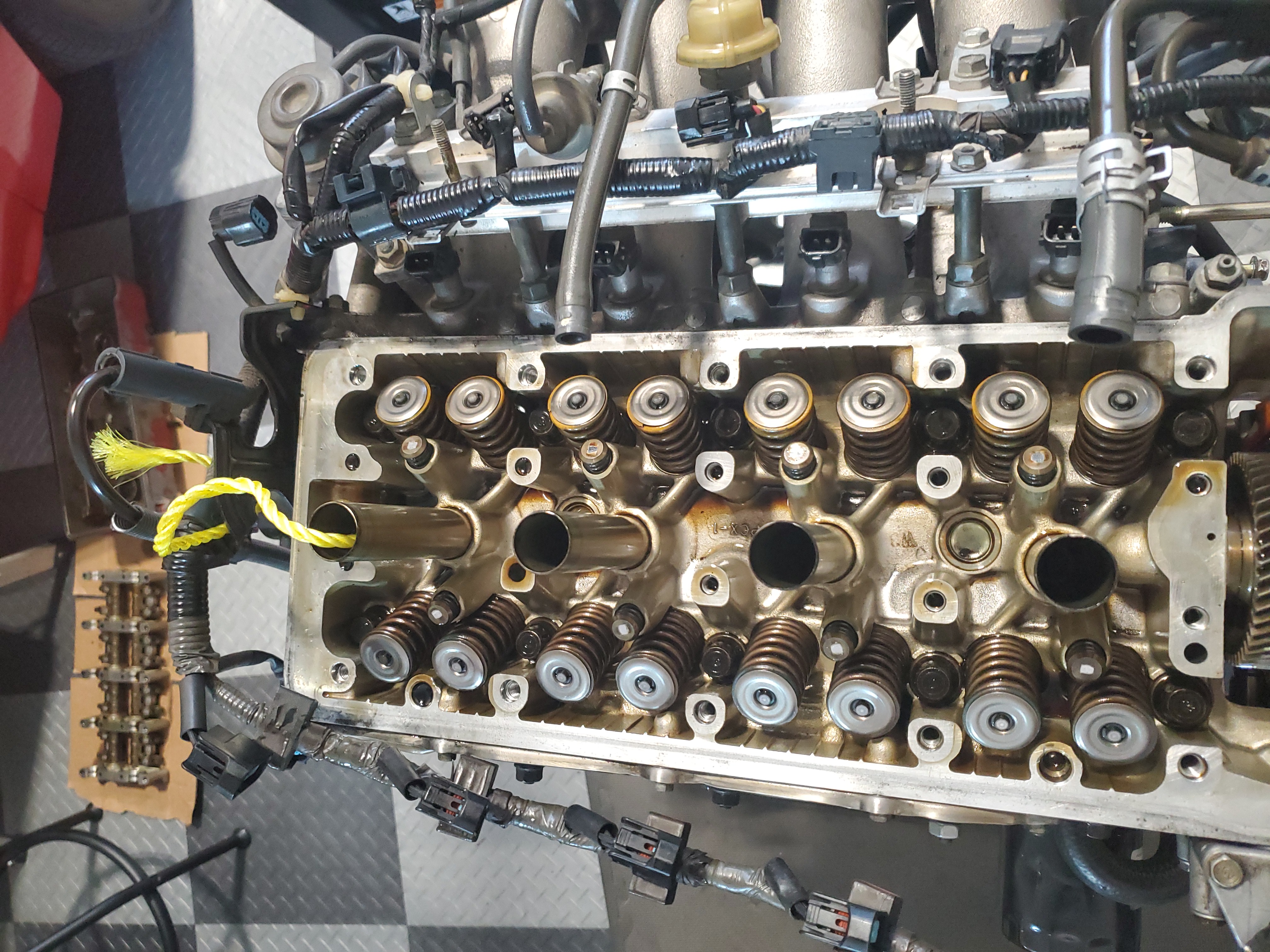

That was the major body work effort done so far. I had bought many other parts to improve the handling of the car such as: poly urathane bushings for all suspension pieces, poly-urathane motor mounts, brake ducts, radiator and hoses, new brake pads and rotors, racing seats and harnesses, roll bar, new exhaust, clutch, pressure plate, front sway bar, new motor seals, valve keepers, and retainers, oil banjo bolts inside the engine block, and new tires. I spent the next year putting on all those parts. It included taking all the suspension apart, motor and transmission out, stripped out the interior, and taking apart of the motor.

From there it was more body work sanding, and painting the car. I have painted the rear half and front bumper twice. The first time the paint did not match very well bceause of a reason I will talk about in another article. However, more recently I reapinted it again with a friend with a more legit setup and a spray gun. I got the paint scanned and color matched much better this time.